The RT-739 Vertical Miniature Conical Twin-Screw Extruder offers significant advantages in the field of polymer synthesis, particularly excelling in material modification, reactive extrusion, and laboratory research. It effectively addresses the challenge of limited sample quantities, which is common for customers conducting tests. This article comprehensively analyzes its applications from three aspects: features, specific use cases, and technical advantages.

1. Key Features and Design Advantages

Efficient Mixing and Shearing Capabilities

The conical twin-screw design, with its gradually narrowing screw spacing, enhances the shear and compression forces applied to the material, making it especially suitable for handling high-viscosity or thermally sensitive materials (e.g., PVC, cross-linked polyethylene). The miniaturized design, coupled with the vertical structure, saves laboratory space while enabling precise control over screw speed, temperature, and pressure to achieve uniform mixing and plasticization of polymer materials.

Reactive Extrusion Functionality

The twin-screw extruder allows for the introduction of chemical reactions during continuous processing, such as mechanochemical synthesis. The shear and extrusion forces can directly trigger solvent-free reactions, making it ideal for the synthesis of fine chemicals like pharmaceutical co-crystals and metal-organic frameworks (MOFs).

Flexibility and Control

The miniaturized equipment supports modular configurations, allowing for easy swapping of screw elements (such as reverse threads or tooth disk components). This flexibility enables adjustment of mixing intensity and residence time to meet the specific process requirements for different polymer synthesis formulations.

2. Specific Application Scenarios

Polymer Blending and Composite Material Preparation

In polymer blending and modification, the conical twin-screw extruder is used to uniformly disperse nano-fillers (e.g., carbon fibers, glass fibers) or functional additives (e.g., flame retardants, antistatic agents), improving the mechanical properties or functionality of materials. For instance, the production of glass fiber-reinforced polypropylene composites relies on the efficient dispersion capabilities of the twin-screw extruder.

Processing of Thermally Sensitive Materials

The extruder is suitable for processing thermally sensitive materials such as PVC and hot-melt adhesives. The vertical design reduces material residence time, and the precise temperature control system helps prevent material degradation, ensuring stable product quality.

Laboratory Research and Small-Batch Production

The miniature equipment is ideal for research and development in universities and corporate R&D departments, such as the synthesis of polymer nanocomposites, bio-based materials, or microcapsules. With its low material requirement (e.g., screw diameter of 22mm) and high energy efficiency, it significantly reduces R&D costs.

Green Chemistry and Solvent-Free Synthesis

Through mechanochemical technology, the extruder facilitates continuous solvent-free reactions, reducing waste emissions. For example, deep eutectic solvents (DES) and drug co-crystals have already been synthesized using the twin-screw extrusion process, demonstrating its scalability potential in fine chemical production.

3. Technical Advantages and Development Trends

Energy Efficiency and Environmental Friendliness

The optimized heating and cooling systems reduce energy consumption, while the solvent-free process aligns with green chemistry principles, minimizing environmental pollution.

Ease of Cleaning

The barrel can be opened 180° for easy cleaning and maintenance of the material chamber and screws. Both the screws and barrel are made of imported mold steel, treated for minimal wear and chemical resistance.

Precise Control of Process Parameters

With zone temperature control, PLC systems, and automated feeding modes, the extruder enables precise regulation of shear-time-temperature profiles, improving product consistency and quality.

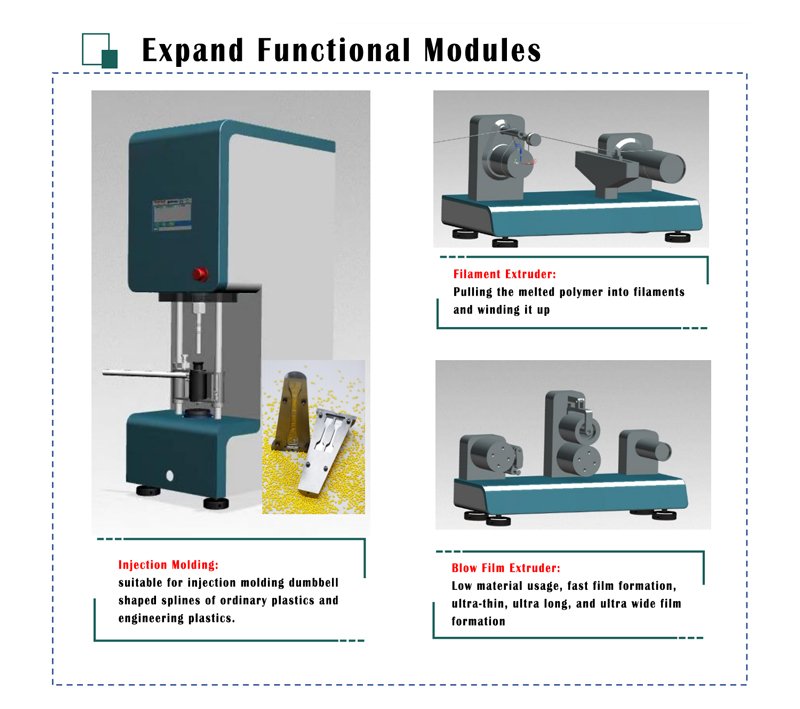

Expandable Interfaces

The extruder can be paired with a mini injection molding machine to produce injection-molded strips. It can also be equipped with film-blowing and spinning die heads to simulate fiber spinning and film casting processes. The operation is straightforward and efficient, with processes like melting, polymerization, extrusion, and injection molding taking only a few minutes.

Conclusion

The RT-739 Vertical Miniature Conical Twin-Screw Extruder, with its efficient mixing, reactive extrusion capabilities, and flexible configuration, has become an essential tool in the polymer synthesis field. It is particularly suitable for laboratory R&D, thermally sensitive material processing, and green chemistry synthesis. As mechanochemical technology continues to evolve, its potential in the pharmaceutical and nanomaterials industries will be further realized.