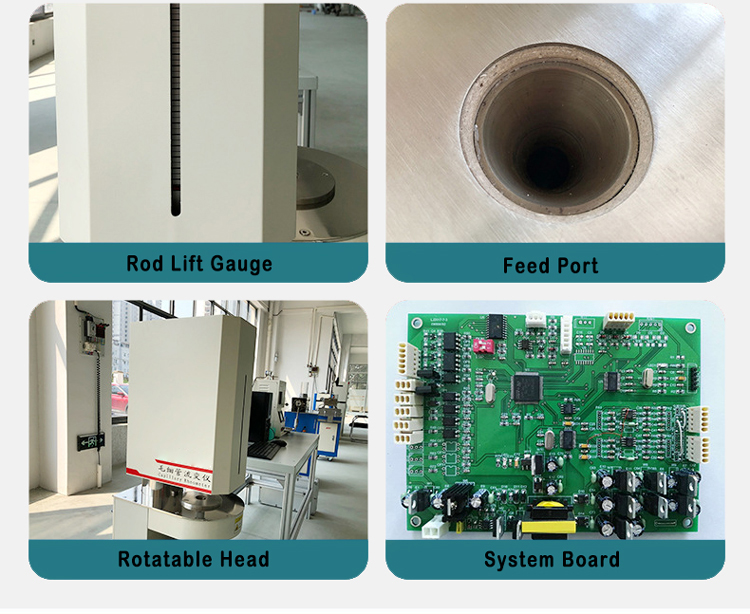

The RT-722 Capillary Rheometer boasts a beautiful appearance and strong stability and is easy to clean. It is also convenient for transportation and installation. This powerful machine can measure the shear rate of plastic processing and temperature conditions. It can determine the melt flowability under shear stress, including adhesion to the wall of thermoplastics and thermoset plastics characterization. The instrument loading device is expertly designed, with hardware and software double closed-loop to achieve stepless speed adjustment and loading force. Both manual and automatic loading controls can be used, making it convenient, fast, and accurate.

Expertise Fuels Focus, Excellence Drives Success

RIGHT: Tech enterprise for R&D, production, and after-sales services.

Our technical team has years of experience and expertise above industry average.

We offer diverse product specs, high quality, and fast delivery.

We provide online and door-to-door support, as well as operation videos.

What Types Of Capillary Rheometers Are There?

Maximum Pressure: 5KN; Oscillating head, easy to clear

For testing of shield tail grease for shield tunneling machines

Test mixed viscous explosives and missile and rocket boosters

What Standards Do Capillary Rheometers Meet?

ISO 11443

Determination of the fluidity of plastics using capillary and slit-die rheometers.ASTM D3835

Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer.

ASTM D5099

Standard Test Methods for Rubber—Measurement of Processing Properties Using Capillary Rheometry.

ASTM D5422

Standard Test Method for Measurement of Properties of Thermoplastic Materials by Screw-Extrusion Capillary Rheometer.

What Tests Can RT-722 Capillary Rheometer Do?

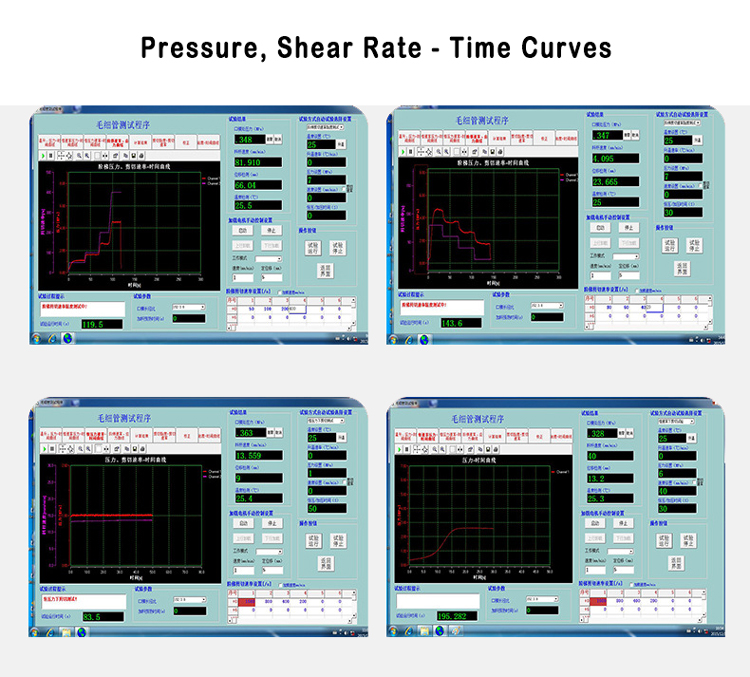

1. Constant Speed Shear Test:

Measuring shear stress and shear rate curve, and shear viscosity and shear rate curve;

2. Constant Pressure Shear Test:

Measure the shear viscosity and shear rate curve;

3. Step Shear Rate Test:

According to user requirements can be set to different shear rates, measure the shear stress and shear rate curve, and shear viscosity and shear rate curve, and in the experimental process according to the changes in the curve to determine the rupture of the melt and the melt’s minimum flow pressure and shear rate;

a) Flow/non-flow Test:

Measure the viscosity and temperature relationship, which can accurately determine the minimum flow temperature of the material;

b) Melt Rupture and Flow Instability:

to study the phenomena of flow instability, including melt rupture and melt fracture.

What Are The Advantages Of RT-722 Capillary Rheometry?

1. A wide range of force values (up to 100kN) and a wide dynamic rate range (225,000:1) allow the test to simulate the real processing environment of the material.

2. Double-hole barrels are used as a standard method to perform shear viscosity measurements and calculate ductile (tensile) viscosity at the same time.

3. Provide a variety of standard high-precision tungsten carbide die, covering a variety of materials and test types.

4. Easily interchangeable melt pressure transducer can meet all the test requirements, equipped with a low noise amplifier to optimize the measurement sensitivity at the inlet of the die.

5. A nitrogen purge option is provided to minimize the possibility of sample degradation.

6. The fume chamber discharges decomposition gas to ensure the safety of operators.

7. The barrel outlet has an open design, compatible with a variety of optional accessories, such as extrusion expansion module, melt cutter, slit die, and melt pull-out strength module.

8. Provide many optional barrel material and size specifications and can measure heat-sensitive, chemically aggressive or water-based samples.

9. RT-722 capillary rheometer also provides a high degree of flexibility for high pressure and high shear rate measurements, whether from polymer melts to ceramics, or from food to coatings.

Customer Satisfaction Is Our Motivation

In recent years, RIGHT company and the national key colleges and universities and scientific research departments developed a number of projects in all walks of life under the support of the steady development, and in accordance with the requirements of the quality of the Hugh Department, “continue to explore and innovate, the courage to open up, and continue to forge ahead, customer satisfaction, never-ending” is the purpose of the enterprise revered.

What Services Are Available Who Purchase Our Capillary Rheometers?

After-sales Service

1. Installation and commissioning: assist the installation of the testing machine, responsible for the transportation and commissioning of the testing machine.

2. Acceptance criteria: the test machine according to the technical annexes of the order for acceptance. Final acceptance in the buyer to carry out the test on the sample provided by the user, and provide test reports.

3. Training: installation and commissioning at the same time, in the operation of the instrument site free training operators 2-3, the operator should be selected by the demand side of the long-term stability of the staff, after training to be able to the basic principles of the equipment, software use, operation, maintenance matters to understand and apply, so that the personnel can independently operate the equipment on the sample for testing, analysis, and at the same time be able to carry out basic maintenance.

3. The software upgrade: lifetime free of charge to provide a new version of the control software.

Warranty

1, the equipment warranty of one year, long-term service, free replacement of parts and components within one year of non-human damage, the warranty period after receiving the user’s invitation, the response time of 2 hours, after confirming the fault with the user, our company will send engineers to the scene within 48 hours to carry out free service, as soon as possible to find out where the fault is located and the cause of the fault, and to the user to timely report on the cause of the failure and troubleshooting methods.

2、Warranty period of man-made damage to parts and components according to the purchase (processing) price charges for replacement.

3, outside the warranty period to continue to provide users with professional and technical services, after receiving the user’s maintenance invitation to send engineers to arrive at the user’s site within 3 days for maintenance, and enjoy preferential treatment for the purchase of spare parts.

4, sensor overload and overpressure damage to the entire circuit is not under warranty.

After-sales Management

My company to achieve computerized management, the implementation of customer regular phone call system, regular review of the work of the equipment, regular electric live to guide the user on the equipment maintenance and testing, so that the normal operation of the equipment to follow up on the customer’s use of the equipment. In order to timely maintenance of equipment.

Seven, 24-hour after-sales service telephone: 13532554730