RT-722D Pumpability Capillary Rheometer

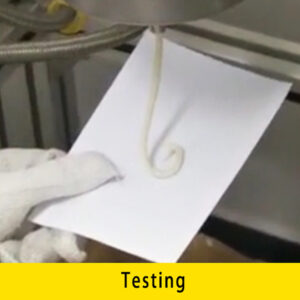

RIGHT combines the U.S. standard ASTM D1092 and domestic capillary rheometer for integrated and innovative instrumentation, which greatly improves the overall performance of shield tail sealing grease and provides effective testing equipment for further product development. Under the specified conditions, the flow rate of grease through a certain aperture capillary tube, expressed in g/min. Accurate equipment than the butter gun only qualitative and not quantitative. Provides an effective solution to compare the pumpability difference of different brands of grease and monitor the stability of different batches of products in our factory. Provide theoretical support to change the formula for different seasons in different regions.

Model: RT-722D

Customizable: OEM, ODM, OBM

Driving Force: 5KN

Warranty: 2 years

Temperature range: | 20-50℃±1℃ |

Temperature rise rate: | 1-5 ℃ / min, continuously adjustable |

Temperature display accuracy: | 0.1℃ |

Pressure range: | 0.5-5Mpa |

Driving force: | 5KN |

Pressure measurement accuracy: | ±0.5%FS |

Pressure resolution: | 0.05Mpa |

Load force resolution: | 0.1N |

| Displacement measurement range: | <250mm |

| Displacement measurement resolution: | 0.06mm |

| Loading speed setting: | 0.01-500mm/min |

| The mouth mold specifications: | Ø 3.8 (mm), 2PCS |

| Mouth mold roughness: | Ra0.4 |

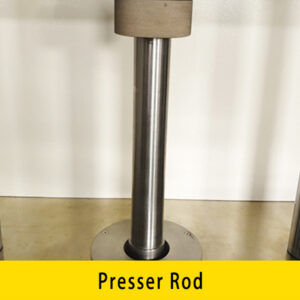

| Plug diameter: | φ44.83 mm |

| Machine size & weight: | 630×400×1900mm, 300kg |

The Shield Tail Seal Grease Pumpability Capillary Rheometer is used to test the pumpability of shield tail seal grease for construction shield machines.

As a kind of sealing material injected into the wire brushes of the tunnel shield machine for underground engineering shield construction, shield tail sealing grease mainly plays the roles of lubrication, sealing and waterproofing. It is injected into the inter-hole gap of the wire brush by pressure, which enhances the sealing performance of the wire brush. Therefore, the pumpability and adhesion of grease are very important indicators.