RT-722B Auto Cleaning Capillary Rheometer

Adopting the streamlined design of the “mouth” frame, the instrument can be expanded into a double-indenter test mode without replacing the main unit. The loading adopts the whole moving double kinetic energy of the upper body moving loading loading mode, the pressurization is more stable. With scale display function, it can visualize the displacement position of material rod. Outwardly removable material chamber, motorized automatic material clearing function, saving time and labor.

Model: RT-722B

Customizable: OEM, ODM, OBM

Driving Force: 10KN (20,30,50KN customized)

Warranty: 2 years

Temperature range: | room temperature ~ 400 ℃ |

Temperature rise rate: | 1-10 ℃ / min, continuously adjustable, and can be rapid temperature rise |

Temperature display accuracy: | 0.1℃ |

Pressure range: | 1-50MPa±0.5% |

Driving force: | 10KN (20,30,50KN customized) |

Pressure measurement accuracy: | ±0.5%FS |

Pressure resolution: | 0.1Mpa |

Speed range: | 0.001-500mm/min |

Deformation measurement accuracy: | ±0.5%FS |

Plug diameter: | φ12 mm (can be customized according to user requirements, price negotiable) |

Plug head area: | 113.04mm2 |

Discharge mold specifications: | Ø 1 × 5, Ø 1 × 10, Ø 1 × 20, Ø 1 × 40 (mm × mm) |

Material of outlet mold: | tungsten carbide |

Power supply: | 220V, 50Hz, power <1000W |

Outside dimensions: | 800 × 450 × 1650mm |

Suitable for the following industrial applications: polymers, coatings, ceramics, metals, pharmaceuticals, sealants, foodstuffs, inks.

1. Evaluate the rheological properties of polymers or suspensions at different shear rates and temperatures.

2. Simulate stretch viscosity dominated processes such as fiber spinning, blow molding, film blow molding, thermo compression molding, etc.

3. Evaluate extrusion behavior in processes such as injection molding, hot melt extrusion, etc.

4. Evaluate material properties at process-related shear rates, e.g., high-speed spraying or printing.

5. Monitor polymer instabilities, such as melt rupture and thermal degradation.

6. Measure elasticity and related properties of materials, such as extrusion swelling.

- The RT-722 capillary rheometer offers highly flexible measurement capabilities for high pressure and high shear rate measurements, whether from polymer melts to ceramics, or from food to coatings.

- A wide force range (up to 100 KN) and a wide dynamic rate range (225,000:1) allow testing to simulate the real processing environment of the material.

- Dual orifice barrels (optional) allow absolute shear viscosity measurements to be made and ductile (tensile) viscosity to be calculated at the same time.

- Numerous optional barrel materials and sizes are available to measure thermally sensitive, chemically aggressive or water-based samples.

- A wide range of standard high precision tungsten carbide orifices are available to cover a wide range of materials and test types Easy interchangeable melt pressure transducers are available to meet all test requirements.

- A low-noise, three-stage amplifier is provided to optimize measurement sensitivity at the orifice inlet.

- An ammonia purge option is available to minimize the potential for sample degradation.

- Fume chamber exhausts decomposition gases to ensure operator safety.

- Proprietary dual-mode rate control algorithms for low and high speed operation to optimize the shear rate range of a given orifice.

- Precise sample temperature control using three independent zone heaters and a 10x DIN accuracy platinum resistance thermometer.

- High temperature (up to 500C) and cooling coil options are also available.

- The rigid “H-frame” design effectively avoids the effects of system flexibility for transient tests such as PVT measurements.

- The barrel outlet has an open design and is compatible with a variety of optional accessories such as extrusion expansion modules, melt cutters, slit dies, melt pull-out strength modules, etc.

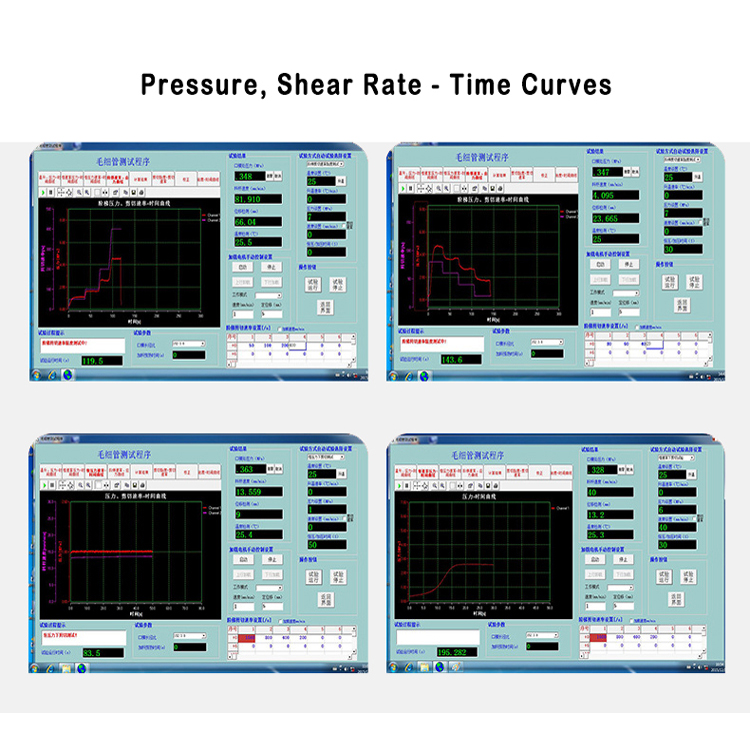

- Convenient and easy-to-use software allows for a full range of tests and analyses, including shear and tensile viscosities, as well as determining sample stability, wall slip and melt breakage.