-150x150.jpg)

-150x150.jpg)

-150x150.jpg)

Single Screw Extruder of Torque Rheometer

Small single-screw extrusion system has a main unit and single-screw extrusion unit combined with different diameters, different length-to-diameter ratios, and different compression ratios according to the need to match the screw and choose different extrusion molds (pipes, sheets, wires, capillary tubes, cable covering, etc.) with other auxiliary functions of the unit, simulating a variety of processing.

Model: SSE20 Single Screw Extruder 20mm

Customizable: logo, color, OEM, ODM, OBM

Screw diameter: 20/25/30mm

Scew speed: 200r/min (adjustable)

Pressure range: 0~100Mpa

Warranty: 2 years

Description

This single screw extruder is suitable for mixing and plasticizing, and extruding engineering plastics, modified plastics, color masterbatches, and other polymers, with the characteristics of uniform dispersion, plasticizing and coloring, filling, and modification. It is suitable for laboratory tests and quality control, teaching research, and small-scale production.

The equipment also has the applicability of many kinds of auxiliary machines, which can be replaced according to the different needs of users, such as water bath pelletizing, film sheet, blown film, conduit, wire, etc.

Main Performance and Characteristics

High precision: international brand melt pressure and temperature sensors are selected for high precision of test data;

Good plasticizing stability: the extruder is driven by an international brand motor, which has good plasticizing stability and can ensure the consistency of materials in the extrusion process;

Adjustable extrusion speed and temperature control: the extrusion speed and temperature can be adjusted in real-time according to the material and production demand;

User formula access: multiple formulas can be stored, which is convenient for users to carry out production and debugging;

Operation safety: emergency stop devices and various safety protections can ensure the safety of operators;

Easy operation: computer-based measurement and control system with a friendly operation interface, easy and convenient operation, and humanized interface design makes the operation more intuitive and easy to understand;

Customizable: according to the different needs of users, it can be customized for different materials and process requirements to meet the individual needs of users.

Application :

- Research and development of new products and new formulas

- Production quality control

- Production process optimization

- Screening and development of materials

- Teaching experiments in universities and research institutes

- Determination of apparent/true viscosity curves

- Extrusion expansion behavior studies

- Small-scale production of small pipes, profiles, films, or sheets

Model | RT-733 |

Product name | Single Screw Extruder |

L/D | 25:1/30:1 |

Screw Dia. | 20/25/30mm |

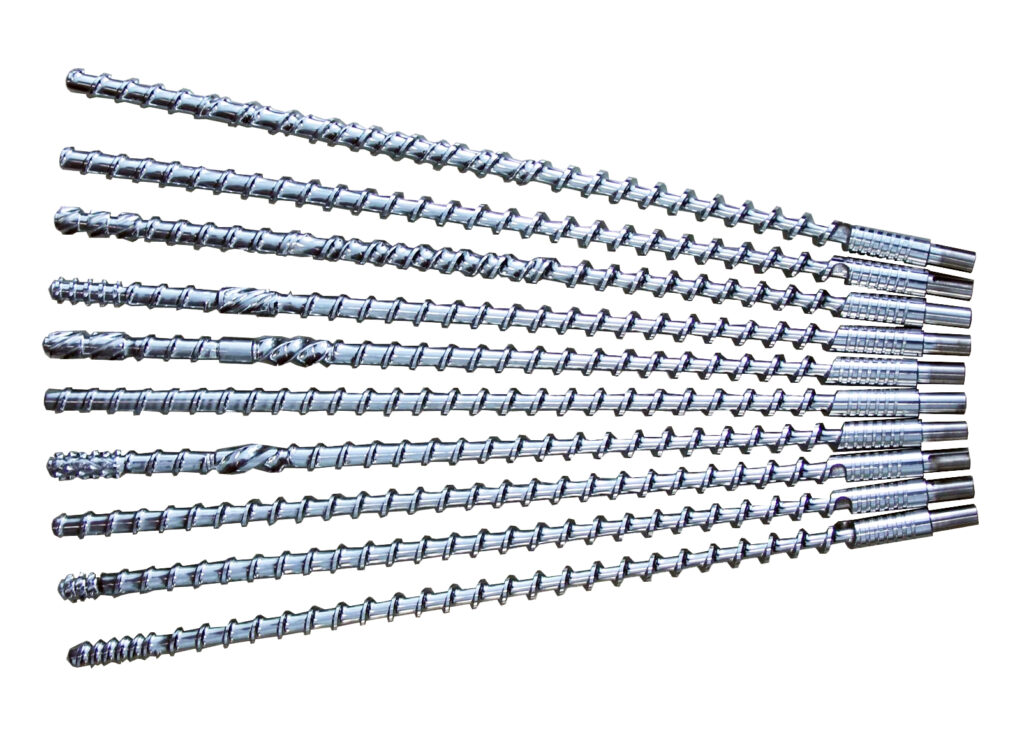

Screw material | 38GrMoAI |

Max. Temp. | RT~350℃ |

Heating Segment | 5 segments |

Dies of Single Screw Extruder

Medical Fine Tube Die

♦Medical Fine Tube Die can be customized by drawing.

♦Material: Medical grade PVC, TPU, TPE, etc.

♦Application: Extrusion of precision medical catheters, catheters for developing lines, multi-lumen tubes, etc.

Capillary Die

♦Through the capillary die head and weight stabilization module to achieve common polymer materials based on capillary rheometer flow characteristics of the measurement

♦Determine the softening point of polymers, melting point, flow point, viscosity viscosity activation energy, thermosetting materials, curing temperature and other performance indicators.

Flat Die A

♦Single-screw calendering experimental line: selection of the main unit, single-screw extruder, sheet die head, and three-roller calender calendering of rubber and plastic materials calendering molding, the production of different specifications of the sheet;

♦Adjustment of the formulation of the material, the process, the test sheet extrusion, and calendering performance, for the development of the relevant sheet polymer material formulations.

Pipe Die

♦Application: The pipe extrusion line can be used to produce pipes, wire channels, profiles, etc.

♦Applicable materials: PP, PE, PVC, ABS, PS, PC, etc.

♦Mechanical structure: pipe single-screw extruder + mold – pipe shaping cooling water tank – pipe haul-off machine – pipe cutting machine + pipe drop frame

Film Casting Die

♦Application: Single-layer casting and sheet extrusion.

♦Testing and evaluation of the casting performance of polymer materials.

♦R&D of new product formulations

♦Optimization of production process parameters

♦Small-scale production of narrow films

♦Quality control

Wire Coating Die

♦Plastic-covered wire use plastic as the cable insulation layer, sheath layer, covered aluminum wire, copper wire, iron wire, rope, etc.

♦Typical raw materials: ABS, PP, PE, PS, PC, PVC, TPR, TPU, PU, PMMA, POM, and so on.

♦Plastic wrapping extrusion line composition:

1、 Unwinding (feeding) device: according to the different cores to be wrapped, choose the corresponding matching device.

2、 Main machine: according to the size and material of the outer layer, different specifications of single-screw extruder or twin-screw extruder can be selected.

3、 Coating die

4、 Cooling and shaping water tank

5、 Traction machine

6、 Cutting or winding equipment

According to the situation, we can choose an EDM tester and diameter meter to accurately measure wrapping quality and adjust the corresponding diameter change parameters.

Film Blowing Die

♦Extrusion blown film is the process of extruding the plastic melt continuously through the mouth die to be extruded under the action of a certain temperature and a certain shear force, and the bifold plastic film is obtained by compressed air blowing, wind ring cooling, and frequency conversion traction.

♦It is mainly used to test the feasibility of blown film of polymer materials and the gelatinous condition within the material, as well as the dispersion of colored dispersions, control mixtures, and extrudates.