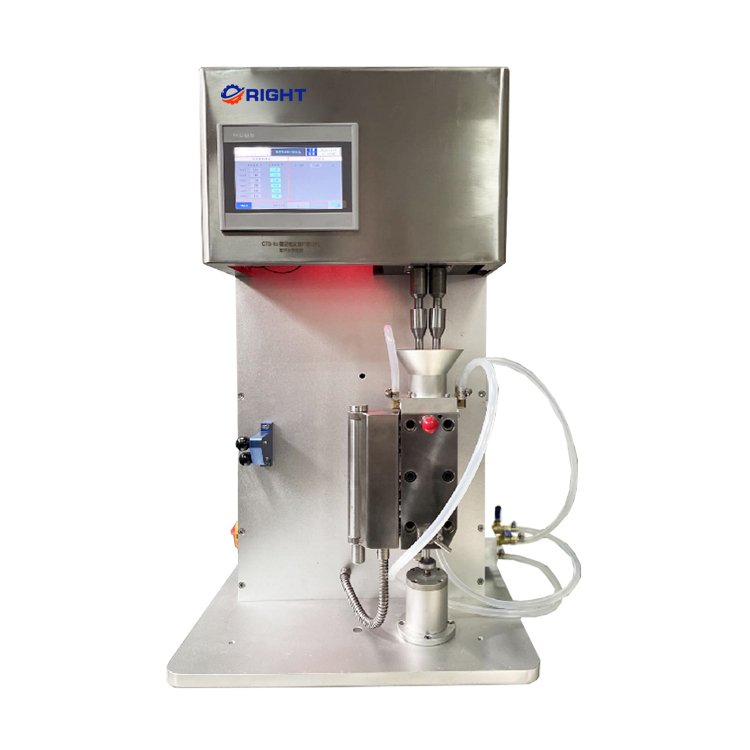

Mini Conical Twin Screw Extruder Machine

Small parallel co-rotating 5.3mm/7.4mm diameter twin-screw extruder for thermoplastic polymer blending and copolymerization extrusion experiments, designed to cope with formulation development. It is intended to be miniaturized according to the user’s needs. It is easy to operate and easy to clean. The minimum required sample size is about 5 grams, significantly reducing time and development costs.

Model: RT-739

Customizable: OEM, ODM, OBM

Volume: 5g/10g/15g

Power: 0.4kw/0.75kw

Warranty: 2 years

Description

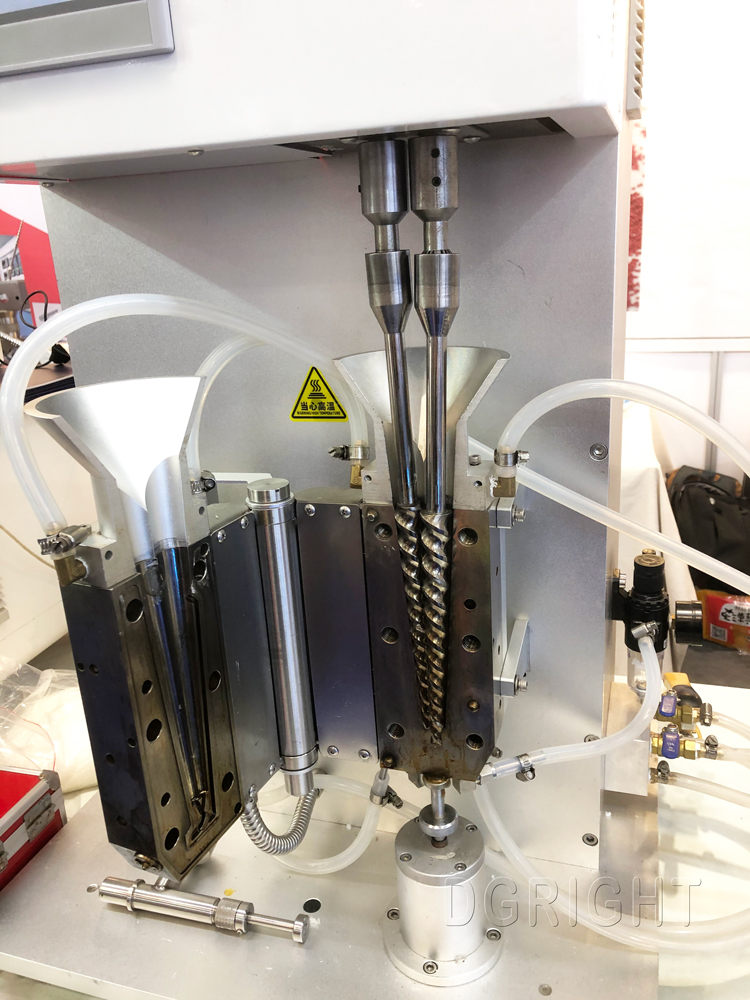

Adopts a mechatronic desktop design, it occupies a small area and is easy to move; the control of the extruder assumes a built-in color touch screen, the barrel structure is vertically open, and the segmented combination screw can be configured by itself according to the application requirements. The screw elements and barrel are designed with the same geometry as the production machine and can quickly be maxed from the laboratory to the production line.

Software:

- Temperature

- Torque

- Pressure

- Speed

- Energy

Applications:

- Quality control and raw material testing;

- Formulation development and optimization;

- Extrusion processing performance testing of different materials;

- Optimization of processing parameters;

- Measurement of rheological and viscosity properties of blends;

- Extrusion of degraded products;

- Small-scale production.

Volume | 5g/10g/15g |

Screw Diameter | 5.3mm/7.4mm |

Screw Length | 110mm/154mm |

Screw Speed | 50~300rpm |

| Torque | 0~5Nm/0~10Nm |

Screw Material | 38CrMoALA |

| Screw Type | Conical Parallel |

| Heating Power | 1.6KW/2.6KW |

| Max. Temp. | 350℃/500℃(specialized for high performance polymers) |